BRAKE SYSTEM INTRODUCTION

The braking system is designed to allow the driver to slow down and stop the vehicle. The master cylinder is connected to the brake pedal by the driver stepped on to force the fluid under pressure to each wheel brake installation.

The braking system is designed to allow the driver to slow down and stop the vehicle. The master cylinder is connected to the brake pedal by the driver stepped on to force the fluid under pressure to each wheel brake installation.

Here hydraulic power was used to force the installation of

brake pad against the revolving rotor plate

or push out the brake

shoe against the

brake drum round.

Parking

brake system

/ handbrake cars

usually use mechanical

means and mounted on the rear wheels. It is

usually used to lock the wheels

of the vehicle when parking

(parking) or braking

in an emergency.

To

increase power which called (servo) are used on the master cylinder

for added power

when braking.

Uses

To be able to stop the vehicle immediately and safely

Uses

To be able to stop the vehicle immediately and safely

To control the vehicle during the journey

For step parking

place

Brake system Must Be Good: -

-Can stop the vehicle quickly when required.

-Must in good condition and in the driver's control at all times.

-Cannot lose braking power.

-Not requiring frequent adjusted.

-Suitable for all speed, weight, and temperature.

-Can stop the vehicle quickly when required.

-Must in good condition and in the driver's control at all times.

-Cannot lose braking power.

-Not requiring frequent adjusted.

-Suitable for all speed, weight, and temperature.

Types Of

brake System:-

1. Mechanical

1. Mechanical

2. The combination of mechanical and hydraulic

3. Hydraulics

4. Wind (pneumatic)

|

| Hydroulic Mechanism |

|

| Hydroulic Systems |

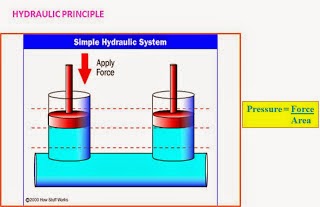

BRAKE TYPE HYDRAULIC SYSTEM

using Pascal's principle, which in principle is stated 'proprietary liquid can move the same pressure in all directions without losing power . As a principle of not be compressed and the pressure on the whole system is the same'.

Component Type Hydraulic System

using Pascal's principle, which in principle is stated 'proprietary liquid can move the same pressure in all directions without losing power . As a principle of not be compressed and the pressure on the whole system is the same'.

Component Type Hydraulic System

|

| Brake Component |

The main parts of hydraulic brakes are as follows:-

1. Brake pedal

2. Master cylinder

3. Pipeline brake

|

| Main Brake System |

4. Wheel cylinder

5. Brake caliper

5. Brake caliper

Liquid system is the most important in Braking system which you can read

"click here"

Master Cylinder

Master cylinder constructed

in two main sections of the

reservoir and master

cylinder body.

Reservoir is provided for supplying brake fluid to control the brake system.

Reservoir is provided for supplying brake fluid to control the brake system.

As part of a cylinder containing a piston

packing paired primary

(primary rubber cup) and packing duplicate

(secondary rubber cup).

Spring is inserted at the end of the piston to allow the piston back

to the original position after braking.

Compensation valve (check valve) was

installed at the end of the cylinder to maintain the pressure in the brake

pipe.

Two output ports are

connected using brake pipelines.

One of the wheel snap ring mounted so as to hold the components in the cylinder from the outside is divided out there guarding dust (dust cover) to prevent dirt from entering the cylinder.

One of the wheel snap ring mounted so as to hold the components in the cylinder from the outside is divided out there guarding dust (dust cover) to prevent dirt from entering the cylinder.

The push rod is used to connect the pedal to

the pressure of the master cylinder.

Pipeline Brake and can be Flexible Hose

Brake pipes and flexible hoses attached to the brake system is to deliver high-pressure fluid to the brake caliper (caliper) and wheel cylinders (wheel cylinder).

Generally flexible hoses mounted on front wheels and caused the front wheel moves

down and up.

Due to the operation of the brake fluid in a

high pressure, pipes and brake hoses must be

made of high

quality materials to prevent

leakage.

Brake pipe made

of steel tube that can withstand corrosion and high pressure. While

the flexible hoses made of rubber

mix of high quality.

Caliper Brake

Brake caliper usually has two types, namely: -

1. fixed caliperCaliper Brake

Brake caliper usually has two types, namely: -

|

| Fix caliper |

Fixed caliper type usually have 2 or 4 piston mounted opposite each other.

Each cylinder there is a bushing (seal).

The bushing serves to prevent brake oil out of the cylinder and piston is pulled back to the original place to provide a running clearance between the pad and the disc surface.

|

| Floating Caliper |

2. floating caliper

Caliper type float (floating) has only one piston, but the size is larger than the size of the piston calipers are used on a regular basis.

The brake calipers are typically used for disk brake type (plate)

| ||||

| floating caliper picture |